Purpose of the experiment:

1 Provide a basis for the new concentrator to purchase equipment models, specifications and quantities.

2 Provide the best ore processing process and the best process conditions for the newly selected concentrator to obtain the best economic benefits.

Test cost: RMB 200,000

The test items are as follows:

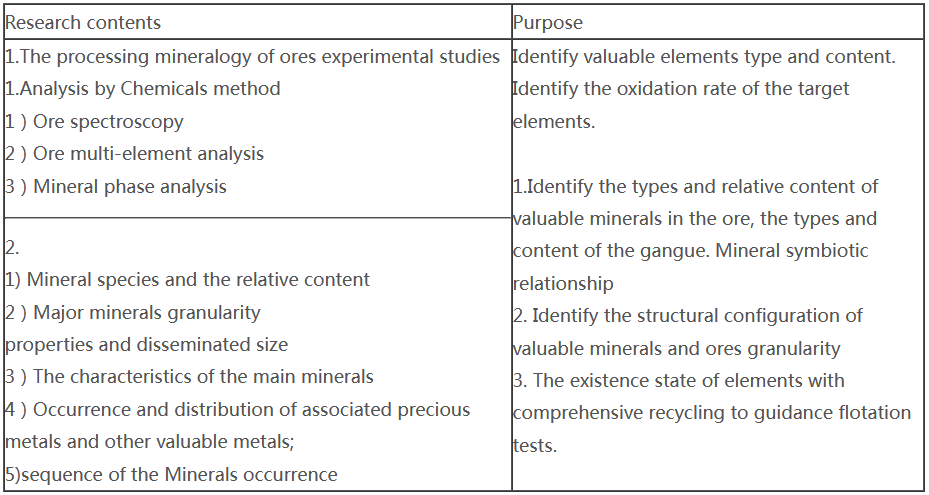

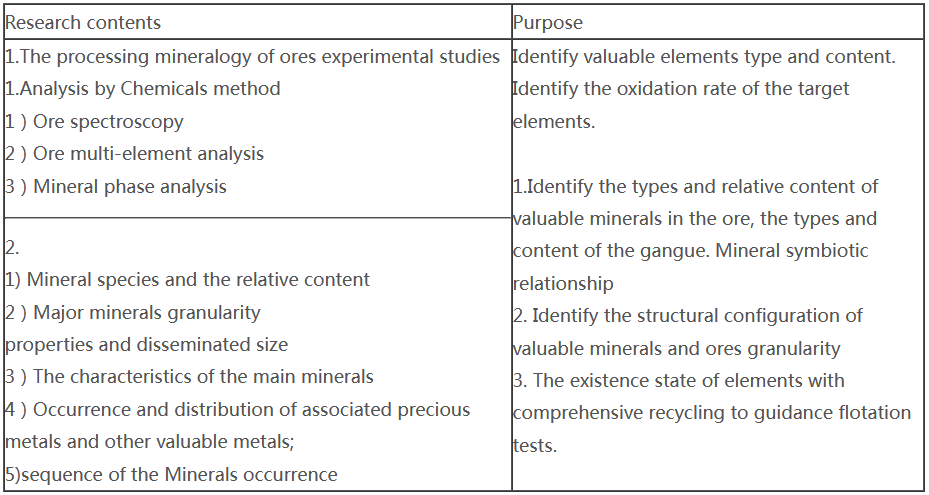

Experimental research project

(1) Experimental study on mineralogy of raw ore

1 chemical research

1) Spectral analysis of raw ore

2) Multi-element analysis of raw ore

3) Analysis of the original mineral phase

2 Identification of ore and rock

1) Mineral types and relative content

2) Embedding characteristics and disseminated particle size of main minerals

3) Output characteristics of major minerals

4) Occurrence and distribution rate of valuable metals such as associated precious metals

5) The order in which minerals are formed, etc. Find out the types and contents of valuable elements in ore

Find out the oxidation rate of the recovered target element

1) Find out the types and relative contents of useful minerals in the ore, and the types and contents of gangue minerals. Mineral symbiosis.

2) Identify the particle size characteristics of useful minerals and the structural structure of the ore.

3) The state of existence of elements can be comprehensively recovered.

In order to guide the beneficiation test.

(2) Beneficiation test

1 flotation test

1) Preselection test

2) Grinding fineness test

3) Flotation time test

4) Flotation agent condition test

1 PH adjuster test

2 vulcanizing agent (activation) test

3 collector test

4 foaming agent test

5 inhibitor test

6 Activator test

5) Process structure comparison test

6) Comprehensive open circuit test

7) Closed circuit test

8) Backwater test

2 magnetic separation test

3 re-election test

4 cyanidation test

5 The specific gravity, mud content, grindability and sedimentation speed of the product are determined.

6 mineral processing products

7 Final recommended process and process conditions

Determine the type, quantity, dosing method, dosing location and dosing sequence of the required mineral processing agent.

Test for Mineral Processing Design